The beauty industry is no stranger to innovation, and one of its most fascinating evolutions is happening right at your fingertips—literally. The rise of fingernail printer machines is reshaping how we view nail art, salon services, and even the role of nail technicians. As we enter 2025, this technology is no longer futuristic—it’s here, it’s growing fast, and it’s turning heads in salons across the globe.

Whether you’re a salon owner, a professional nail technician, or simply a nail art enthusiast, understanding the future of fingernail printer machines in the nail industry and their impact on nail technicians is crucial. Let’s explore how this technological marvel is transforming tradition into something ultra-modern.

What Are Fingernail Printer Machines?

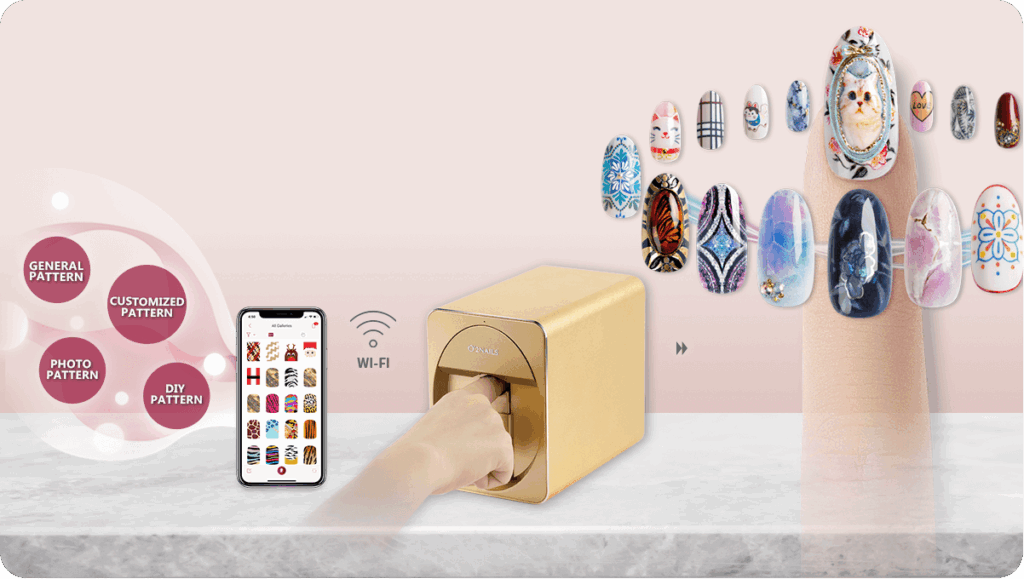

Fingernail printer machines are compact, high-tech devices that digitally print intricate designs onto fingernails using inkjet technology. These machines offer salon-quality results in a fraction of the time, often connected to smartphones or tablets for endless design options.

Types of Nail Printers in 2025:

- Standalone salon-grade machines: High-speed, bulk-use for professional settings

- Compact home-use printers: Consumer-friendly, app-controlled

- AI-integrated models: Capable of adjusting designs to nail shape and size

These machines are becoming smarter and more versatile, appealing to both professionals and home users.

History of Nail Art: From Manual to Digital

Long before machines entered the picture, nail art was a manual craft—a blend of steady hands, creative minds, and years of practice. With the digital revolution, traditional tools like brushes and stamps have been joined (not replaced yet) by digital solutions.

- Pre-2000s: Polish, acrylics, and freehand art

- 2010s: Introduction of decals, stickers, and stamping kits

- 2020s: Onset of automation and smart printing

This timeline shows a natural evolution rather than an abrupt replacement.

Technological Features of Modern Nail Printers

Modern fingernail printers in 2025 come packed with features once thought to be science fiction:

- AI-powered design customization

- High DPI resolution for photo-realistic prints

- Bluetooth and Wi-Fi connectivity

- Integration with design apps and social media

Some devices even offer voice commands, allowing hands-free operation—a dream for busy salons.

How Fingernail Printers Work: Step-by-Step Process

Here’s a breakdown of how these machines work:

- Prep the Nail – Clean, base coat, and align the finger inside the device.

- Choose the Design – Select from a library or upload a custom image.

- Print – In under 30 seconds, the design is printed.

- Seal – A top coat is applied to secure the artwork.

The process is quick, consistent, and almost error-free when set up correctly.

Benefits of Fingernail Printer Machines for Salons

Salon owners are taking note—and for good reason:

- Speed: Complete intricate designs in under a minute

- Customization: Cater to every client’s unique taste

- Efficiency: Serve more clients without overworking staff

- Marketing edge: Attract tech-savvy and trend-conscious customers

These machines offer a solid return on investment when used strategically.

Impact on Nail Technicians: The Pros

Not everything about automation is a threat. In fact, many nail technicians are finding opportunities in this shift:

- Upskilling: Learning to operate printers can increase value

- Reduced fatigue: Less time doing fine detail work by hand

- Faster service = more tips: Clients appreciate speed and novelty

- New creative avenues: Blending manual art with machine prints

It’s less about replacement and more about redefinition.

Impact on Nail Technicians: The Cons

That said, this shift is not without challenges:

- Job security fears: Will machines take over traditional roles?

- Devaluation of craftsmanship: What happens to years of hand-painting experience?

- Tech learning curve: Not all nail techs are comfortable with gadgets

There’s an emotional and economic toll to consider.

Nail Techs vs. Nail Printers: A Collaborative Future?

Rather than a battle between man and machine, a hybrid model is emerging:

- Tech-enhanced artistry: Machines print base designs, humans add embellishments

- Signature styles: Nail techs use printers for consistency, then apply their unique flair

- Two-tiered services: Offer clients manual or digital options

Collaboration seems more sustainable than competition.

Cost Analysis and ROI for Salon Owners

Investing in a fingernail printer machine may feel like a bold move, but for many salon owners, the return on investment (ROI) is promising. Here’s why:

- Initial Costs: Prices range from $500 for home-use models to over $5,000 for professional-grade machines.

- Operational Costs: Regular ink replacements, electricity, and occasional software updates.

- Service Revenue: Salons can charge premium rates for custom-printed nail art, sometimes up to $10-$20 extra per session.

With the ability to service more clients faster, the payback period for the investment can be as short as 3–6 months in high-traffic locations.

Client Preferences: Human Touch or Machine Precision?

Customer feedback has revealed mixed emotions:

- Younger Clients (Gen Z, Millennials): Lean toward novelty and customization. They love posting their machine-designed nails on social media.

- Older Clients (Gen X, Boomers): Tend to value the human touch and long-standing relationship with their technician.

Salons can benefit by offering both options to meet different client expectations.

Global Market Trends and Adoption Rates

Different regions are embracing this technology at varying paces:

- Asia (China, South Korea, Japan): Leading the charge with mass adoption in urban salons.

- North America: Rapid growth, especially in cities like New York, Los Angeles, and Toronto.

- Europe: Mixed reactions; strong presence in fashion-forward cities like Paris and Milan.

The global market for digital nail art is projected to surpass $1.2 billion by 2027, driven largely by consumer demand and competitive salon environments.

Regulations and Hygiene Standards

With new tech comes new responsibilities. Regulatory bodies are beginning to catch up:

- Sanitation Protocols: Machines must be cleaned between uses to prevent infections.

- Ink Safety Standards: Only FDA-approved, non-toxic inks should be used.

- Usage Guidelines: Training and machine-specific certifications may become mandatory in some regions.

This ensures client safety while promoting industry professionalism.

Training and Certification for Operating Nail Printers

Operating a fingernail printer requires a different skill set than traditional nail artistry. Fortunately, the industry is adapting:

- Online Courses: Platforms like Udemy and Coursera offer introductory modules.

- Manufacturer Training: Most brands offer bundled onboarding sessions.

- Accredited Certification Programs: Emerging in cosmetology schools.

This offers a career-boosting opportunity for nail technicians ready to embrace the future.

The Ethical Debate: Artistry vs Automation

Some argue that machines dilute the soul of nail artistry. Others view them as tools that expand creative potential.

- For: Artists can design digitally, experiment with patterns, and even print their own artwork onto nails.

- Against: Automation may undermine the value of handmade craftsmanship and originality.

The answer likely lies in striking a balance between tradition and innovation.

Sustainability and Eco-Friendly Aspects

Fingernail printer machines may actually have environmental benefits over time:

- Less polish waste: No need to open multiple bottles for one design.

- Refillable ink cartridges: Reduce landfill contributions.

- Fewer disposables: Less need for tools like brushes and stamps.

With sustainability becoming a client priority, this could be a selling point for eco-conscious salons.

The Future Outlook: Will Nail Techs Become Obsolete?

The short answer: No—but the role will evolve.

- Future nail techs will likely be part artist, part tech operator.

- Demand for personalization will ensure humans stay in the loop.

- Creativity and empathy, two human strengths, remain irreplaceable.

Like many industries, adaptability will be key to survival and success.